The Ultimate Guide to Fiber Optic Splice Closures: 2024 Edition

Introduction

Fiber Optic Splice Closures are important components in the telecommunications industry. These closures are responsible for protecting and organizing fiber optic cables, ensuring that connections are fast and reliable. It’s crucial for anyone involved in setting up or maintaining fiber optic networks to understand how these closures work.

This Ultimate Guide to Fiber Optic Splice Closures: 2024 Edition aims to provide you with a comprehensive overview of these vital devices. You’ll learn about choosing the right closure, proper installation methods, and effective maintenance techniques. The guide also explores the latest trends and advancements that are shaping the future of fiber optic splice closures, giving you valuable insights to stay ahead in the ever-changing world of telecommunications.

Use this updated information to expand your knowledge and become an expert in fiber optic splice closures.

What is a Fiber Optic Splice Closure?

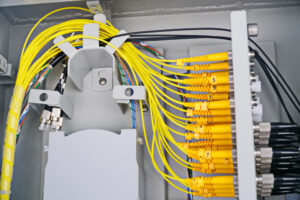

A Fiber Optic Splice Closure is a critical component in fiber optic networks, designed to protect and organize spliced fiber optic cables. These closures safeguard the fiber splices from environmental conditions such as moisture, dust, and mechanical damage, ensuring network reliability and longevity.

Key Components and Structure

A typical closure consists of several key components:

- Outer Shell: Provides physical protection and environmental sealing.

- Splice Tray: Organizes and holds the spliced fibers securely.

- Cable Entry Ports: Allow for easy entry and exit of fiber optic cables.

- Sealing Mechanisms: Ensure the closure is watertight and resistant to external contaminants.

Types of Fiber Optic Splice Closures

Different types of closures cater to various applications and environments. Here’s a breakdown:

Dome Closures

- Design: Cylindrical shape with a dome-like cap.

- Applications: Ideal for aerial, underground, and direct burial installations.

- Features: High capacity for cable entry points, excellent sealing performance.

Inline Closures

- Design: Elongated shape, allowing cables to enter from both ends.

- Applications: Suitable for long-haul applications where inline connections are necessary.

- Features: Streamlined design for minimal signal loss, robust environmental protection.

Horizontal Closures

- Design: Flat or slightly curved shape that lays horizontally.

- Applications: Commonly used in buried or wall-mounted setups.

- Features: Easy access for maintenance, high fiber capacity.

Vertical Closures

- Design: Upright orientation resembling a tower.

- Applications: Often found in manholes or handholes where vertical space is utilized.

- Features: Efficient use of space, sturdy construction for demanding environments.

Understanding the different types of closures helps you choose the right one based on specific requirements such as installation environment, cable management needs, and maintenance considerations. Each style offers unique benefits tailored to various network configurations.

Benefits of Using Fiber Optic Splice Closures

1. Environmental Resistance

One major benefit of fiber optic splice closures is their robust environmental resistance. These closures are designed to protect fiber optic cables from harsh external conditions, including extreme temperatures, moisture, and UV radiation. This ensures the longevity and reliability of the network.

2. Durability

Durability is another critical advantage. Made from high-strength materials such as stainless steel or reinforced plastic, fiber optic splice closures are built to withstand mechanical stress and physical impacts. This durability reduces the risk of damage during installation or maintenance, ensuring continuous network performance.

3. Easy Installation Process

Fiber optic splice closures offer an easy installation process. Many closures come pre-assembled or with comprehensive installation kits that include detailed instructions. This simplifies the setup process, allowing technicians to efficiently deploy these closures without extensive training.

4. Maintenance Convenience

Maintenance convenience is a significant factor when considering fiber optic splice closures. These closures are often designed with accessibility in mind, featuring easily removable covers and modular components. This makes it easier to inspect and service the cables inside, reducing downtime and maintenance costs.

5. Cost-Effectiveness

Cost-effectiveness is a notable benefit of using fiber optic splice closures. While the initial investment might be higher compared to other solutions, the long-term savings in terms of reduced maintenance costs, decreased downtime, and extended lifespan outweigh the upfront expenses. These closures provide a reliable solution that minimizes total cost of ownership.

Using fiber optic splice closures offers numerous advantages that contribute to the efficiency and reliability of telecommunications networks. The combination of environmental resistance, durability, easy installation, maintenance convenience, and cost-effectiveness makes these closures an essential component in modern fiber optic infrastructure.

Factors to Consider When Choosing and Installing Fiber Optic Splice Closures

Choosing Fiber Optic Splice Closures

When selecting the right fiber optic splice closure, several critical factors come into play:

- Cable Capacity: Assess the number of fiber cables your network requires. Ensure the closure can accommodate current needs and potential future expansions.

- Environmental Conditions: Consider the environment where the closure will be installed. Outdoor installations require closures that can withstand harsh weather conditions, while indoor closures might not need such robust protection.

- IP Rating Requirements: The Ingress Protection (IP) rating indicates the level of protection against dust and water. For outdoor installations, a higher IP rating is essential to prevent moisture ingress and ensure long-term reliability.

- Accessibility for Maintenance: Choose a closure design that allows easy access for maintenance and troubleshooting. Features like re-entry capability can save time and effort during routine inspections and repairs.

Installing Fiber Optic Splice Closures

Proper installation of fiber optic splice closures is vital for maintaining network integrity. Follow these steps for a successful setup:

- Pre-Installation Preparations:

- Conduct a thorough survey of the installation site to identify potential hazards and ensure proper placement.

- Gather all necessary tools and materials, including splice trays, sealing kits, cable ties, and protective gloves.

- Mounting the Closure:

- Secure the closure on a stable surface using appropriate mounting brackets or hardware.

- Ensure the mounting location provides adequate space for cable routing and future maintenance.

- Cable Preparation:

- Strip the outer jacket of the fiber cables carefully to expose the individual fibers.

- Clean and organize the fibers to avoid any damage or contamination.

- Splicing Fibers:

- Use precision tools to splice the fibers accurately. Fusion splicing is often preferred for its low-loss connections.

- Place spliced fibers into splice trays within the closure, ensuring they are neatly arranged to prevent any bending or stress.

- Sealing the Closure:

- Apply sealing kits as per manufacturer guidelines to protect against environmental elements.

- Check for any gaps or potential entry points for moisture or dust.

- Testing Connections:

- Perform optical time-domain reflectometer (OTDR) tests to verify signal integrity across splices.

- Address any issues detected during testing before finalizing the installation.

By considering these factors when choosing and installing fiber optic splice closures, you can ensure a robust and reliable fiber optic network capable of meeting current demands while being prepared for future growth.

Maintenance and Troubleshooting Guide for Fiber Optic Splice Closures

Maintaining Fiber Optic Splice Closures ensures the longevity and reliability of your fiber optic network. Regular inspections and proper cleaning procedures are crucial. Adhering to manufacturer guidelines is essential to avoid compromising the integrity of the closure.

Regular Maintenance Practices

- Inspection: Periodically check closures for physical damage, signs of wear, or environmental intrusion. Look for any abnormalities in the appearance of the closure.

- Cleaning Procedures: Use appropriate cleaning agents and tools to remove any dirt, dust, or debris. Avoid using harsh chemicals that might damage the closure materials.

- Adherence to Manufacturer Guidelines: Follow specific instructions provided by the manufacturer regarding maintenance intervals and recommended practices. This includes checking seals, gaskets, and other components that ensure the closure’s environmental protection.

Common Issues and Troubleshooting

Fiber Optic Splice Closures can encounter issues that may affect network performance. Understanding these problems and knowing how to address them is vital.

Loose Connections

Over time, connections within the splice closure may become loose due to vibrations or improper handling. Regularly inspect connections and ensure they are secure. If a loose connection is identified, retighten according to the manufacturer’s specifications.

Water Ingress

Water ingress is a significant concern as it can lead to signal loss or complete failure of the fiber optic link. Ensure that all seals are intact and properly seated during inspections. If water ingress is detected:

- Immediate Action: Open the closure carefully and dry out any moisture.

- Seal Inspection: Check all seals and gaskets for damage or wear. Replace if necessary.

- Reassembly: Reassemble the closure following proper procedures to ensure all seals are correctly positioned.

Regular maintenance combined with prompt troubleshooting can significantly extend the life of your Fiber Optic Splice Closures and maintain optimal network performance.

Future Trends and Innovations in Fiber Optic Splice Closures

Emerging Technologies and Design Advancements

The landscape of fiber optic splice closures is changing quickly, thanks to new technologies that make them more efficient and effective. Here are two important trends to watch:

Integration of Smart Features

Splice closures are becoming smarter with the integration of advanced features. These features allow for remote monitoring and control, making it easier to identify and fix problems in real-time. For example, sensors inside the closures can detect changes in temperature, humidity, and potential issues, sending notifications to maintenance teams for immediate action.

Adoption of Modular Designs

Another trend is the adoption of modular designs. Instead of having fixed configurations, these closures use interchangeable parts that can be easily modified or expanded. This flexibility makes it simpler to adapt to different network requirements without major changes. Providers can quickly adjust their setups as needed, ensuring minimal downtime and uninterrupted service.

Impact on the Telecommunications Industry

These innovations have significant implications for the telecommunications industry:

- Improved Reliability: Smart closures enable proactive maintenance, leading to fewer service outages and lower costs compared to manual inspections.

- Faster Issue Resolution: With remote monitoring capabilities, problems can be identified and addressed more quickly, reducing the time it takes to restore services.

- Better Protection: The development of environmentally-resistant materials ensures that fiber optic networks remain stable even in harsh conditions, extending their lifespan.

Supporting the Growth of 5G Networks

As demand for high-speed internet continues to rise, especially with the rollout of 5G networks, these advancements in splice closures become crucial:

- They enable faster data transmission rates, supporting the increased bandwidth requirements of 5G technology.

- Their durability and reliability ensure that network infrastructure can keep up with the demands of 5G connectivity.

- The flexibility offered by modular designs allows for easier expansion and upgrades to accommodate higher network traffic.

Key Takeaways

- Smart Features: Enable remote monitoring and diagnostics.

- Modular Designs: Offer flexibility and scalability.

- Environmentally-Resistant Materials: Enhance durability in extreme conditions.

- Support for 5G Expansion: Meet growing demands for high-speed data transmission.

These innovations not only improve operational efficiency but also position telecom providers to meet evolving customer expectations effectively. The continuous improvement in fiber optic splice closure technology underscores its significance in maintaining robust and reliable communication networks.

Conclusion

Staying updated on the latest developments in Fiber Optic Splice Closures is crucial. Reputable sources and industry publications can provide you with the most current information, helping you make informed decisions.

Well-chosen and properly maintained closures play a critical role in ensuring reliable fiber optic networks. They protect your infrastructure from environmental hazards and mechanical stress, maintaining optimal performance.

Utilize this Ultimate Guide to Fiber Optic Splice Closures: 2024 Edition as a resource for understanding, choosing, installing, and maintaining these essential components. Your network’s reliability depends on the quality and upkeep of its splice closures. Keep this guide handy and refer to it regularly to stay ahead in the ever-evolving telecommunications landscape.

FAQs (Frequently Asked Questions)

What is a Fiber Optic Splice Closure?

A Fiber Optic Splice Closure is a protective device designed to organize and protect fiber optic cables. It typically consists of key components such as the housing, tray, and sealing elements to ensure the integrity of the cable connections. There are different types of closures available in the market, including Dome Closures, Inline Closures, Horizontal Closures, and Vertical Closures, each with unique features and applications.

What are the benefits of using Fiber Optic Splice Closures?

Fiber Optic Splice Closures offer various advantages such as environmental resistance, durability, easy installation process, maintenance convenience, and cost-effectiveness. These closures provide protection to the fiber optic cables in challenging conditions and ensure reliable network performance.

What factors should be considered when choosing and installing Fiber Optic Splice Closures?

When choosing a Fiber Optic Splice Closure, it is important to consider cable capacity, environmental conditions, IP rating requirements, and accessibility for maintenance purposes. The installation process requires careful attention to pre-installation preparations and best practices to ensure a successful setup.

How should Fiber Optic Splice Closures be maintained and troubleshot?

Regular maintenance of Fiber Optic Splice Closures is essential through inspection, cleaning procedures, and adherence to manufacturer guidelines. Common issues that may arise with these closures include loose connections or water ingress, which can be addressed through proper troubleshooting techniques.

What are the future trends and innovations in Fiber Optic Splice Closures?

The future of Fiber Optic Splice Closures involves emerging technologies and design advancements such as the integration of smart features for remote monitoring and control. These innovations are expected to have a significant impact on the telecommunications industry as it evolves to meet growing demands.

How can readers stay updated on the latest developments in Fiber Optic Splice Closures?

Readers are encouraged to stay updated on the latest developments in Fiber Optic Splice Closures through reputable sources and industry publications. It is important to recognize the critical role that well-chosen and properly maintained closures play in ensuring reliable fiber optic networks.